HiCOS Plus

Operation, visualization and monitoring of mobile and stationary test systems

The control system HiCOS Plus operates, visualizes and monitors the HV-test system. The tests can be conducted manually or via automatic test sequences.

Key features are its online access possibility and its active support of preventive maintenance and optimized service calls.

Your Advantages at a Glance

-

Unified and intuitive operating philosophy

-

Online access possibility

-

Open interfaces for system integration

-

Reduction of downtime costs

-

Reduction of failure probability

-

Easy upgrade of older test systems

-

SIL 3 standard for safe operations

Product Information

Select language

Select language

Key feautures

-

Easy and intuitive handling

-

Web access to local test management

-

Preventive maintenance and optimized service

Housing

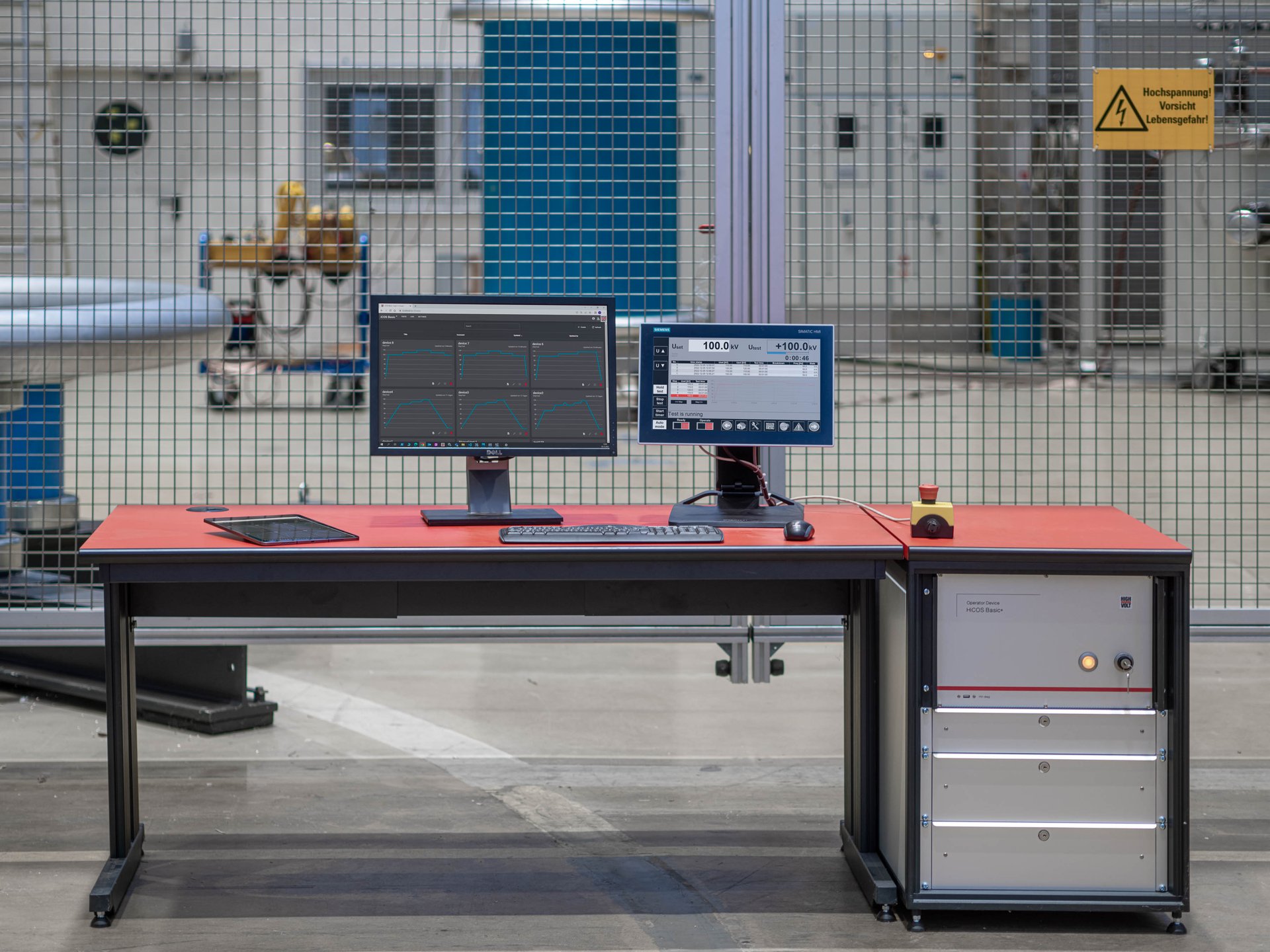

The housings contain the hardware of the HiCOS modules and of the measuring devices. The racks and boards are modified to ensure a high electromagnetic shielding and the reliable operation of the control and measuring devices. The housings consist of aluminum profiles and steel walls. The connection between walls and profiles is electro-magnetically proof.

The operator rack is provided for the control and measurement equipment. Its lockable rollers allow an easy transportation within the test field.

Safety measures

Safety measures ensure the safety and health of the operators at work. The control of each HIGHVOLT test system includes the safety functions Emergency OFF and Safety loop that fulfill the requirements of the standard IEC 62061 (e.g., redundant safety loop). It is possible to include external emergency STOP buttons, door contacts and to interconnect several test systems. All safety measures from HIGHVOLT fulfill the latest requirements of international standards.

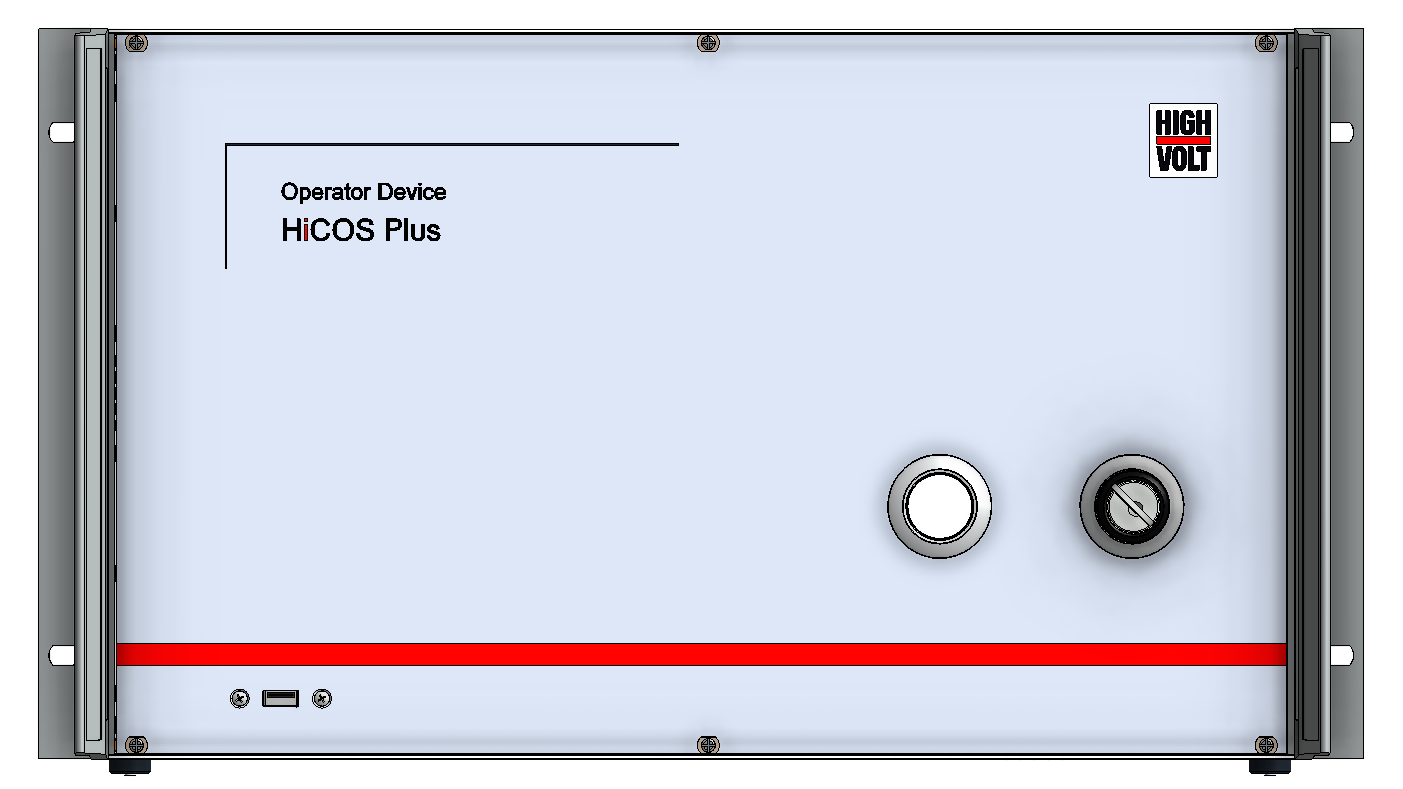

Operator device

The operator device is the interface between test system and operator. The control firmware iCOS Plus will be installed.

The 19“-rack unit contains a DIN rail PC on which, among others, the visualization runtime and the web services for accessing external devices (e.g., customer PC) are running. The router integrated into the 19“ rack unit is the interface to the test system for web access.

The Siemens industrial touch display is equipped with a high-resolution 16 million colour widescreen display with large viewing angle, which enables easy handling, operation and visualization of the test system.

To avoid electromagnetic interference, communication between the operating device and the test system takes place via fiber optic cable (ETHERNET).

Design

There are two different design types. All design types are equipped with an emergency STOP button and a key switch.

The design type G includes a wireless keyboard and a mouse, for operating the industrial PC. The design type E includes a keyboard with integrated mouse, designed as 19” built-in (1 HU) for operating the industrial PC.

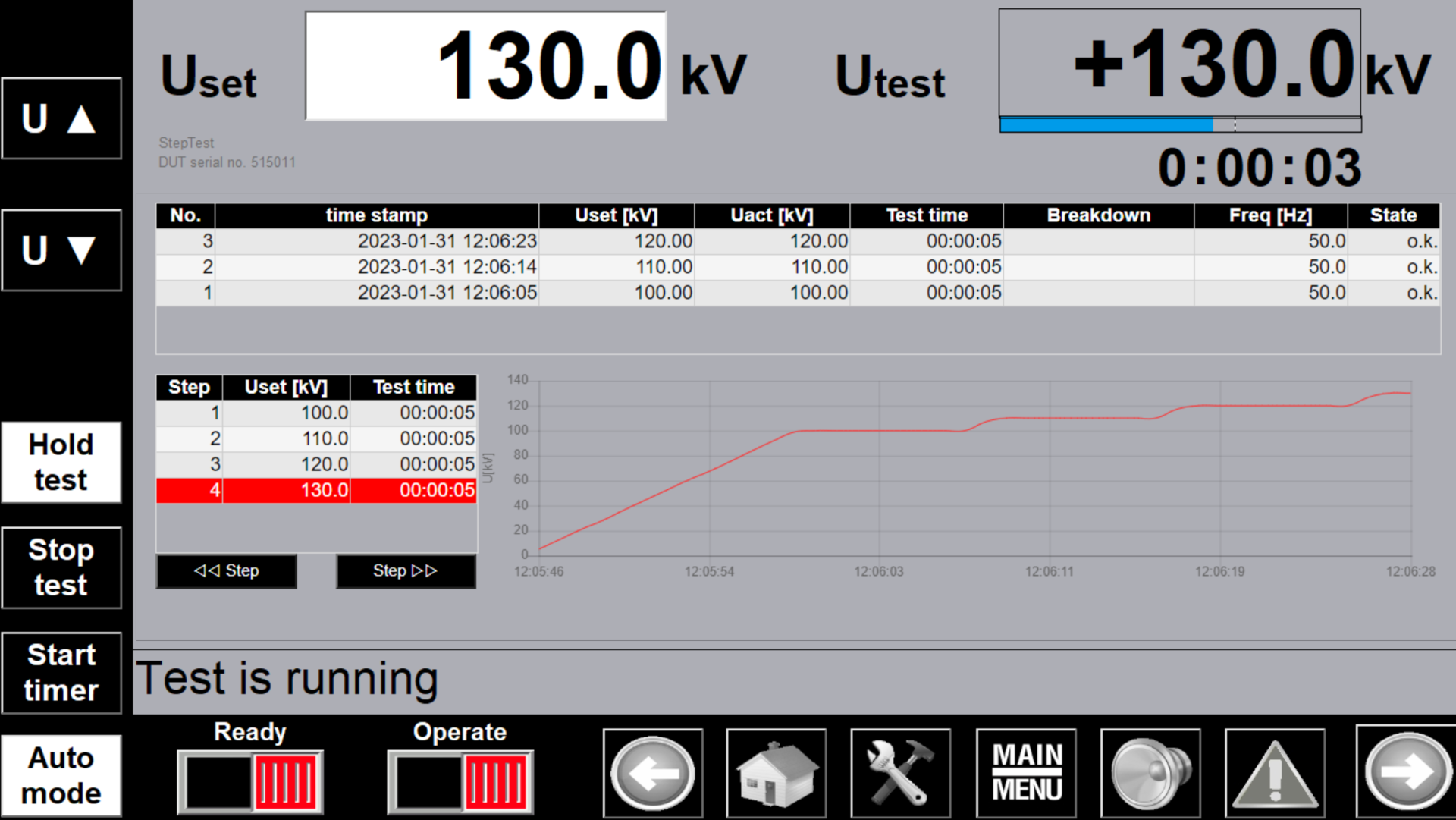

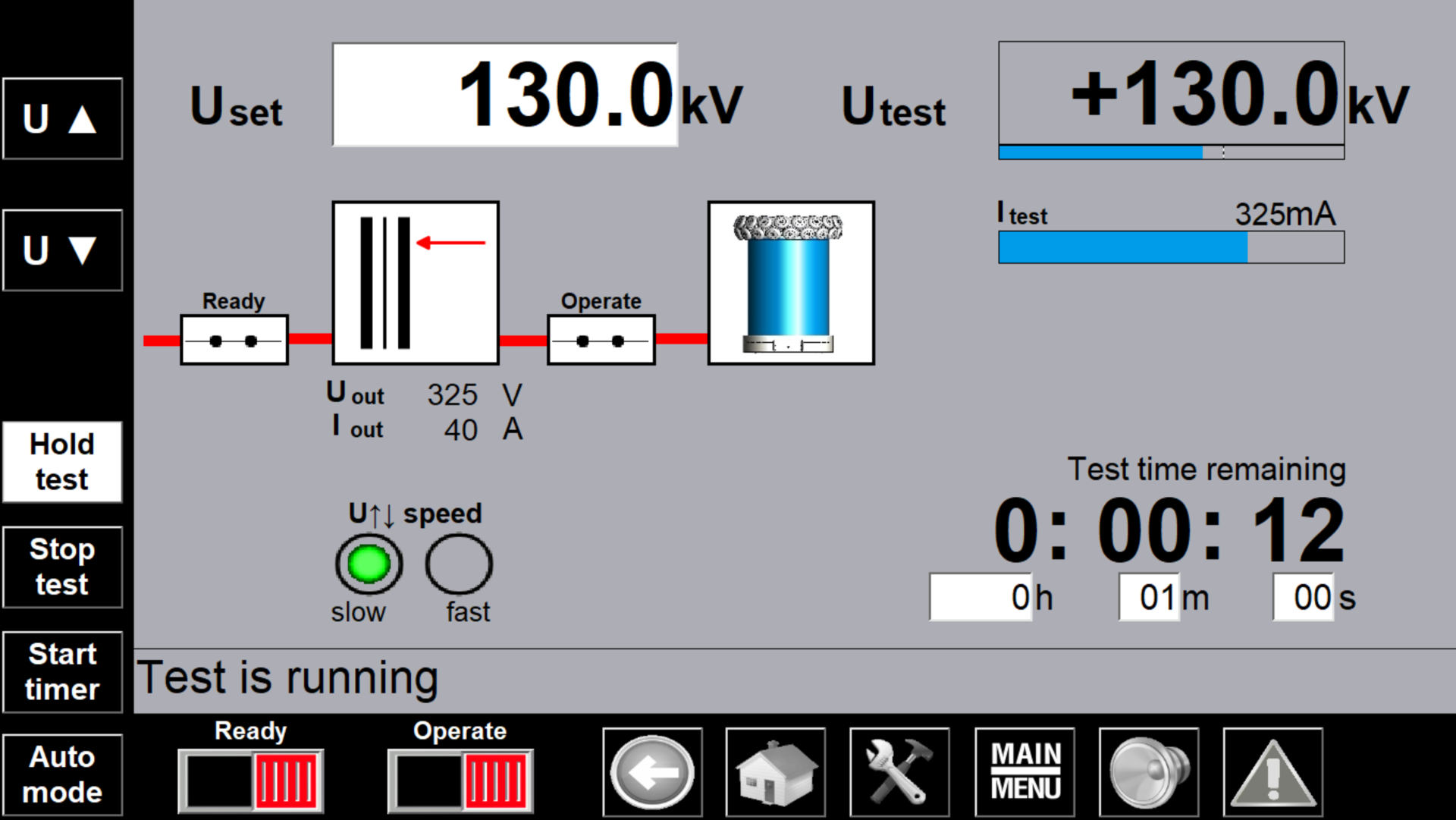

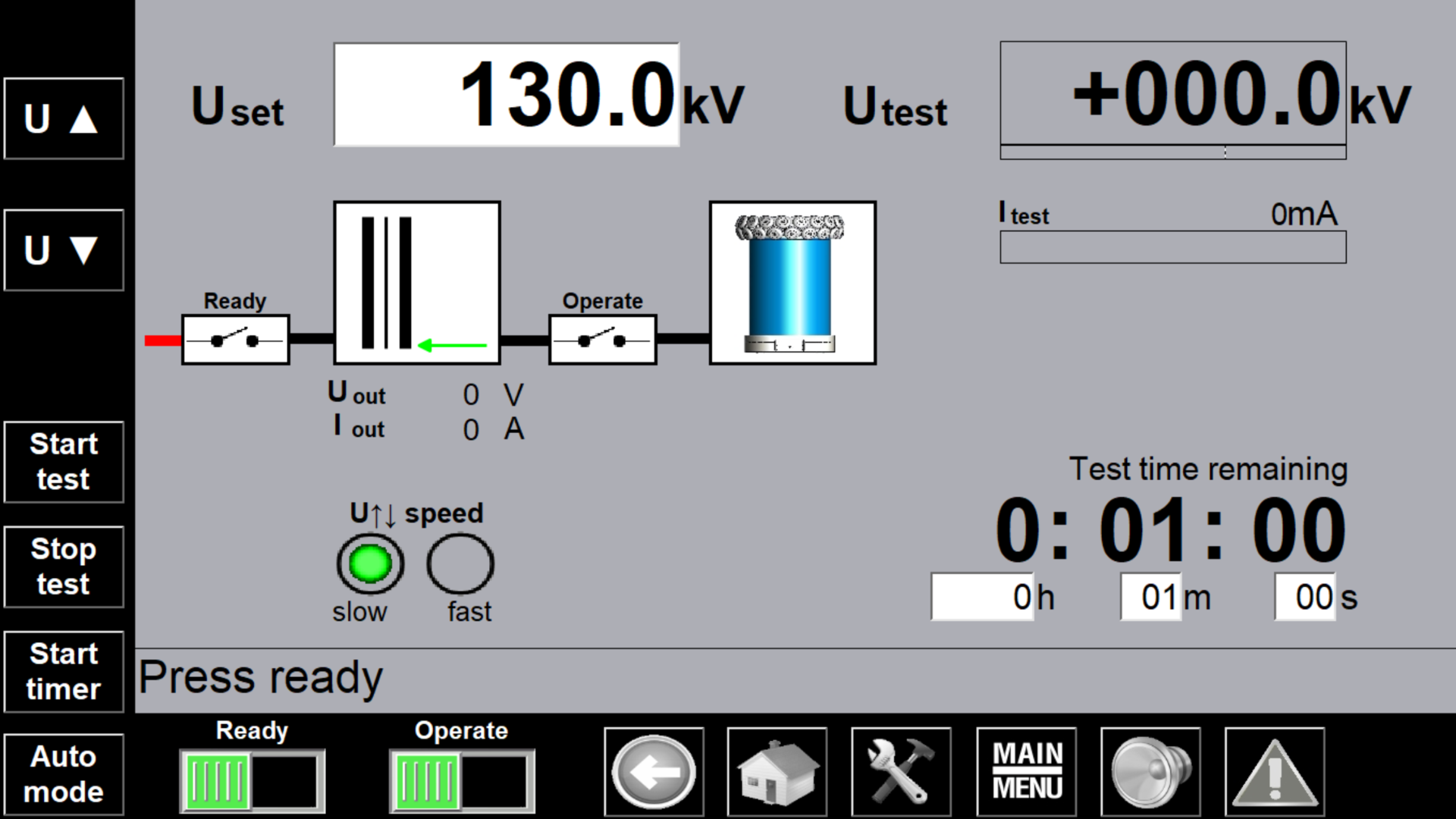

Test control

The firmware iCOS Plus installed both on the operator device and on the PLC comprises all applications and services required for control and the test management of the test system.

Tests can be performed in manual mode, semi-automatic mode or are automatically controlled by starting user-defined test sequences.

The local control and test management is characterized by:

- Operation of the test system

- Creation, parameterization, and storing of tests

- Recording, evaluation, and storing of measurement values

- Interfaces for embedding measuring devices

- Provision of test reports for external clients

- Interface to HIGHVOLT Portal

- Interface (REST-API) for database access, e.g., via the ERP system

- Web interface for test management

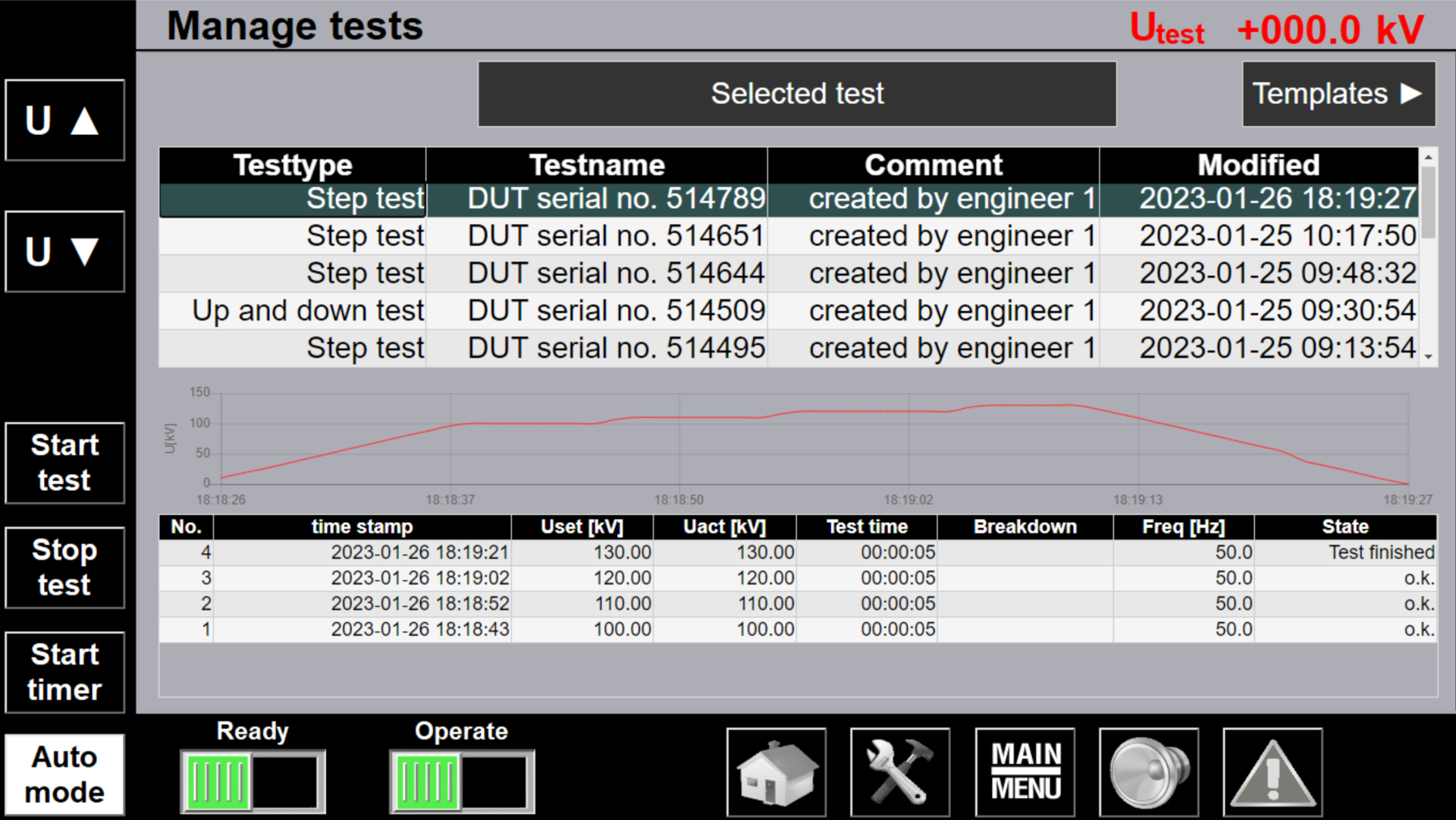

Test management

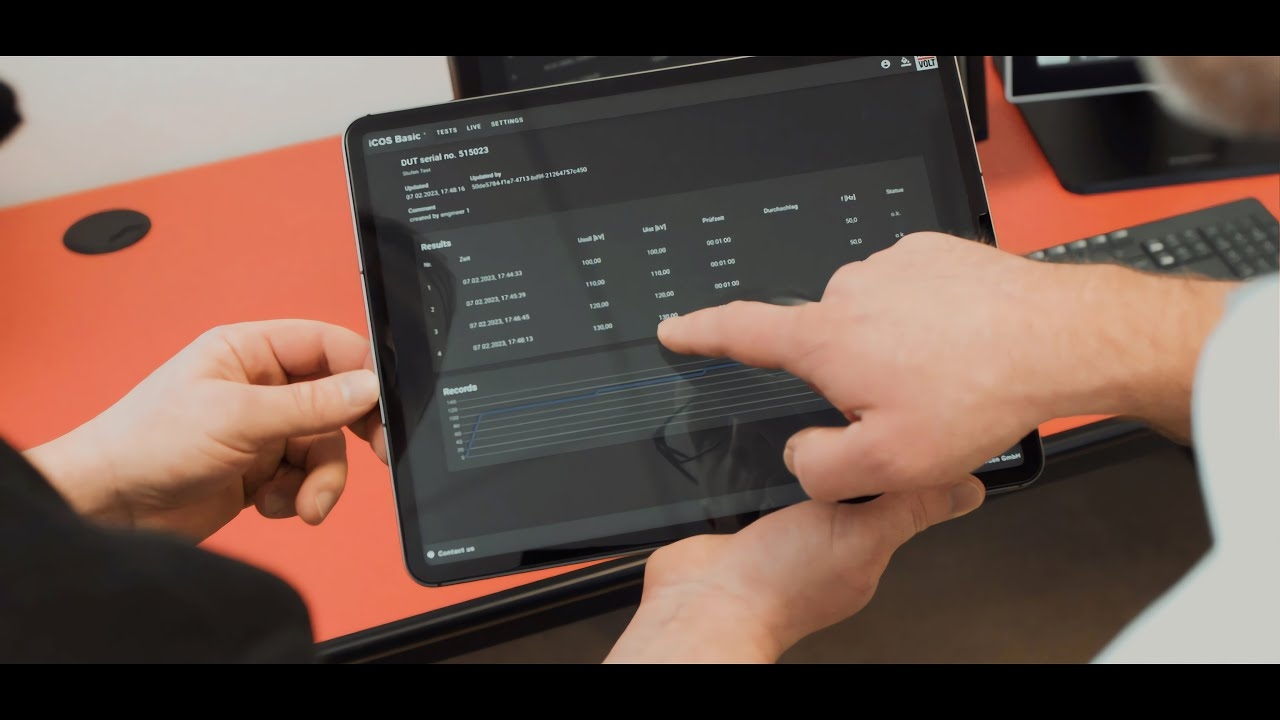

The local test management can be accessed via the iCOS web interface or directly via the operating device.

The test management has the following functionality:

- Creation, parameterization, and storing of test sequences

- Selection between several test types e.g.:

- "Manual test" for manual performance of a test

- "Step test" for automatic performance of a test sequence

- "Up-and-down test" for automatic performance of an up-and-down test

- Recording, evaluation, and storing of measurement values

PLC firmware

For each type of test systems, different firmware versions are available. The main functions of the PLC firmware e.g. for a AC resonant test system with transformer are characterized by:

- Main switch/operating switch on/off

- Status indication of main switch/operating switch

- Warning and error messages of the test system

- Increase/decrease voltage

- Preselection of test voltage and test time

- Preselection of two regulating speeds

- Display of voltage and current limits for system protection

- Operation of compensation (optional)

- Password protection of important system settings

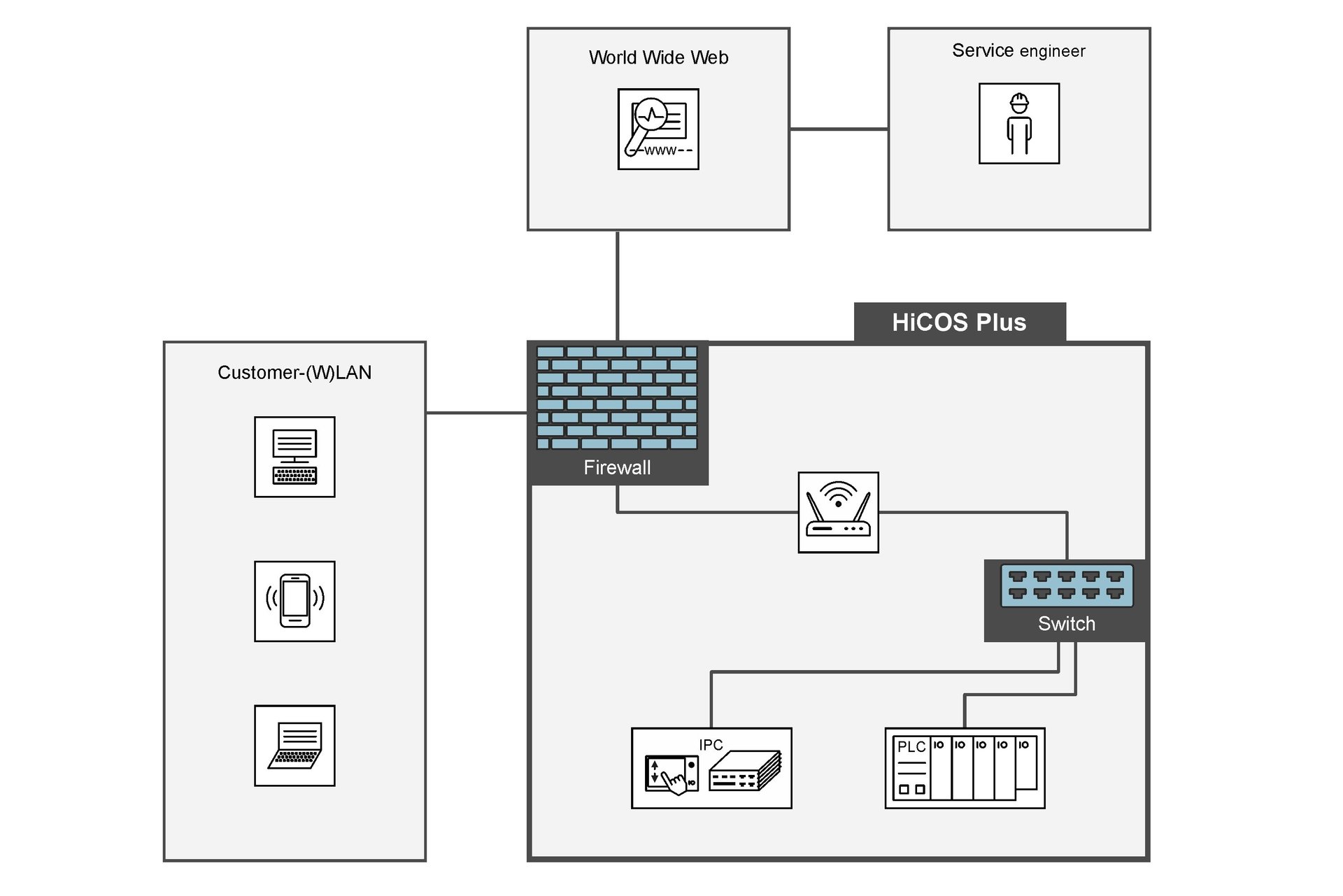

The web interface is characterized by:

- Access to the local test management via the customer's intranet or (W)LAN of the test system for user-friendly creation, parameterization, and storing of tests

- Connection of the customer intranet via the router integrated in the operator device

- Firewall to protect the test system

- Authentication service for access restriction of unauthorized users

- Creation of test reports (Excel) on the customer premises equipment

- Creation of customer-specific templates (Excel) for test report recording

- Live view of the ongoing test

Device interfaces

Device interfaces are used to connect hardware components to the control firmware iCOS Plus. Depending on the hardware, three different types of interfaces are available:

- Automatic interface for direct access to the control of the hardware component and for reading out of measurement values

- Semi-automatic interface for reading out measurement values

- Manual interface for entering test results in the local database

HIGHVOLT Maintenance Portal

A key feature of the control system HiCOS Plus is the online comparison of the test system operating data with the HIGHVOLT maintenance portal. This is especially useful for data on components subject to wear, and system messages providing information about the maintenance status of the test system. This does not involve the exchange of test results.

The HIGHVOLT Maintenance Portal provides the customer with an overview of the conditions of its test systems. The user gains access by logging in via the browser of its PC.

The operating data of the test systems can be evaluated and specific measures can be taken to avoid operational failures. In addition to the resulting maintenance optimization, aging and defective components can be replaced in time, which avoids downtimes and maximizes the test system's availability.

Additional hardware

HiCOS Customized extends HiCOS Plus with modular PC software of additional software tools, additional hardware packages and other customized applications according to customer requirements.

Additional hardware components:

- Industrial PC

- Laptop

- Display (built-in)

- Display (stand-alone)

- Keyboard (built-in)

- Keyboard (wireless)

- Printer (color inkjet)

- Printer (color laser)

Additional software applications

HiCOS Customized extends HiCOS Plus with modular PC software of additional software tools, additional hardware packages and other customized applications according to customer requirements.

Additional software applications:

- Development of software applications according to customer requirements

- Software integration of third-party devices

- Test field visualization enables separation in different test areas

- Preparation and testing in different areas at the same time

- Optimal utilization of available space

- Full status control over laboratory

Housing

The housings contain the hardware of the HiCOS modules and of the measuring devices. The racks and boards are modified to ensure a high electromagnetic shielding and the reliable operation of the control and measuring devices. The housings consist of aluminum profiles and steel walls. The connection between walls and profiles is electro-magnetically proof.

The operator rack is provided for the control and measurement equipment. Its lockable rollers allow an easy transportation within the test field.

Safety measures

Safety measures ensure the safety and health of the operators at work. The control of each HIGHVOLT test system includes the safety functions Emergency OFF and Safety loop that fulfill the requirements of the standard IEC 62061 (e.g., redundant safety loop). It is possible to include external emergency STOP buttons, door contacts and to interconnect several test systems. All safety measures from HIGHVOLT fulfill the latest requirements of international standards.

Operator device

The operator device is the interface between test system and operator. The control firmware iCOS Plus will be installed.

The 19“-rack unit contains a DIN rail PC on which, among others, the visualization runtime and the web services for accessing external devices (e.g., customer PC) are running. The router integrated into the 19“ rack unit is the interface to the test system for web access.

The Siemens industrial touch display is equipped with a high-resolution 16 million colour widescreen display with large viewing angle, which enables easy handling, operation and visualization of the test system.

To avoid electromagnetic interference, communication between the operating device and the test system takes place via fiber optic cable (ETHERNET).

Design

There are two different design types. All design types are equipped with an emergency STOP button and a key switch.

The design type G includes a wireless keyboard and a mouse, for operating the industrial PC. The design type E includes a keyboard with integrated mouse, designed as 19” built-in (1 HU) for operating the industrial PC.

Test control

The firmware iCOS Plus installed both on the operator device and on the PLC comprises all applications and services required for control and the test management of the test system.

Tests can be performed in manual mode, semi-automatic mode or are automatically controlled by starting user-defined test sequences.

The local control and test management is characterized by:

- Operation of the test system

- Creation, parameterization, and storing of tests

- Recording, evaluation, and storing of measurement values

- Interfaces for embedding measuring devices

- Provision of test reports for external clients

- Interface to HIGHVOLT Portal

- Interface (REST-API) for database access, e.g., via the ERP system

- Web interface for test management

Test management

The local test management can be accessed via the iCOS web interface or directly via the operating device.

The test management has the following functionality:

- Creation, parameterization, and storing of test sequences

- Selection between several test types e.g.:

- "Manual test" for manual performance of a test

- "Step test" for automatic performance of a test sequence

- "Up-and-down test" for automatic performance of an up-and-down test

- Recording, evaluation, and storing of measurement values

PLC firmware

For each type of test systems, different firmware versions are available. The main functions of the PLC firmware e.g. for a AC resonant test system with transformer are characterized by:

- Main switch/operating switch on/off

- Status indication of main switch/operating switch

- Warning and error messages of the test system

- Increase/decrease voltage

- Preselection of test voltage and test time

- Preselection of two regulating speeds

- Display of voltage and current limits for system protection

- Operation of compensation (optional)

- Password protection of important system settings

The web interface is characterized by:

- Access to the local test management via the customer's intranet or (W)LAN of the test system for user-friendly creation, parameterization, and storing of tests

- Connection of the customer intranet via the router integrated in the operator device

- Firewall to protect the test system

- Authentication service for access restriction of unauthorized users

- Creation of test reports (Excel) on the customer premises equipment

- Creation of customer-specific templates (Excel) for test report recording

- Live view of the ongoing test

Device interfaces

Device interfaces are used to connect hardware components to the control firmware iCOS Plus. Depending on the hardware, three different types of interfaces are available:

- Automatic interface for direct access to the control of the hardware component and for reading out of measurement values

- Semi-automatic interface for reading out measurement values

- Manual interface for entering test results in the local database

HIGHVOLT Maintenance Portal

A key feature of the control system HiCOS Plus is the online comparison of the test system operating data with the HIGHVOLT maintenance portal. This is especially useful for data on components subject to wear, and system messages providing information about the maintenance status of the test system. This does not involve the exchange of test results.

The HIGHVOLT Maintenance Portal provides the customer with an overview of the conditions of its test systems. The user gains access by logging in via the browser of its PC.

The operating data of the test systems can be evaluated and specific measures can be taken to avoid operational failures. In addition to the resulting maintenance optimization, aging and defective components can be replaced in time, which avoids downtimes and maximizes the test system's availability.

Additional hardware

HiCOS Customized extends HiCOS Plus with modular PC software of additional software tools, additional hardware packages and other customized applications according to customer requirements.

Additional hardware components:

- Industrial PC

- Laptop

- Display (built-in)

- Display (stand-alone)

- Keyboard (built-in)

- Keyboard (wireless)

- Printer (color inkjet)

- Printer (color laser)

Additional software applications

HiCOS Customized extends HiCOS Plus with modular PC software of additional software tools, additional hardware packages and other customized applications according to customer requirements.

Additional software applications:

- Development of software applications according to customer requirements

- Software integration of third-party devices

- Test field visualization enables separation in different test areas

- Preparation and testing in different areas at the same time

- Optimal utilization of available space

- Full status control over laboratory

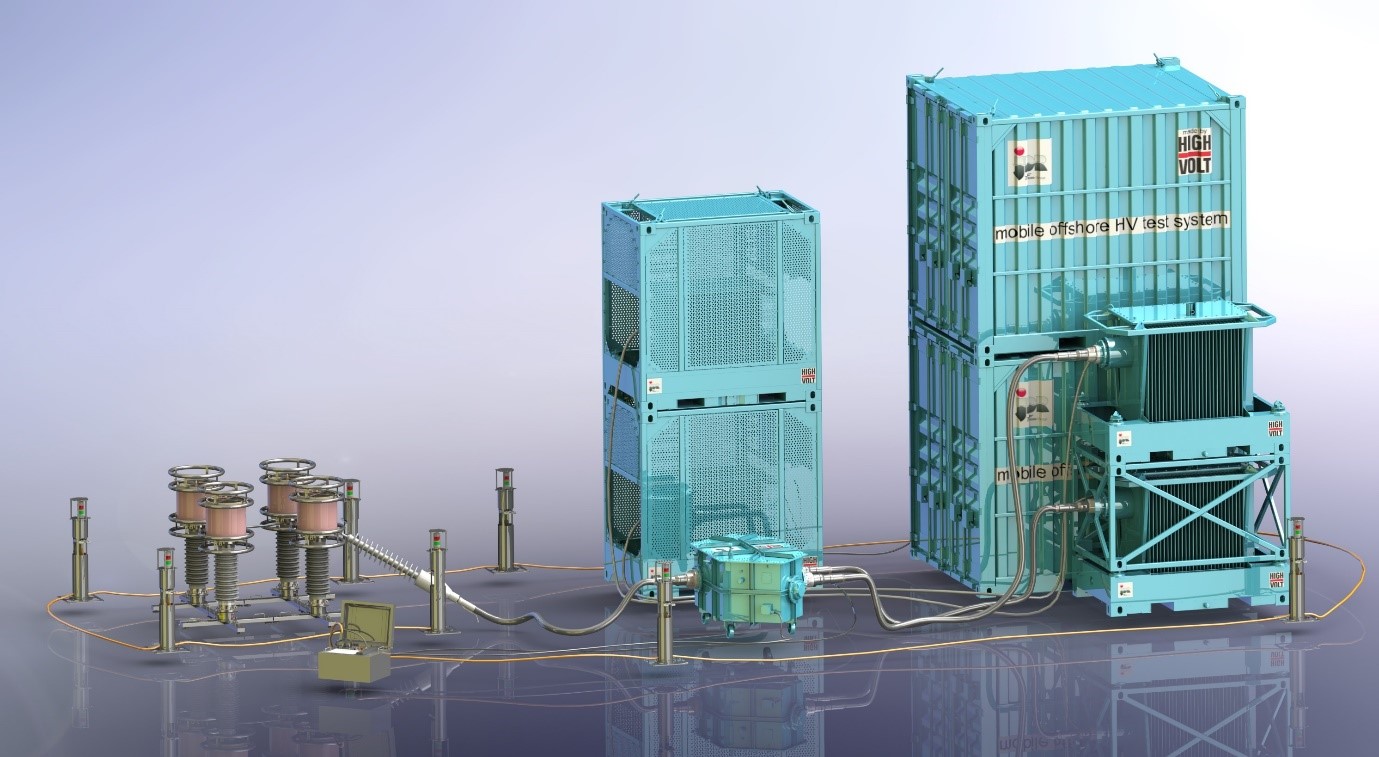

Use cases in a smart factory

Use cases in a smart factory

HIGHVOLT test system as smart IoT device in a smart factory

- Open interfaces for system integration

- Access by web browser and web API for

- Creation, parameterization and storing of tests

- Evaluation of measuring data and test results

- Download of test reports

- Upload of customer-specific test report templates

- Access by web browser for live view of the ongoing test

- Cloud-based evaluation of the test system's operating data for preventive maintenance and optimized service

- High cyber security level